Watch PlantSwitch turning agricultural plant byproducts into “plastic” on Spectrum 1 News North Carolina. The groundbreaking company has secured $17.5M in funding and has its bioplastic processing facility located in Sanford, North Carolina, where it will be producing 50 Million+ LBS of bioplastics each year. Currently, large companies like Sysco and US Foods have converted over to using PlantSwitch bioplastic for all of their brands.

|

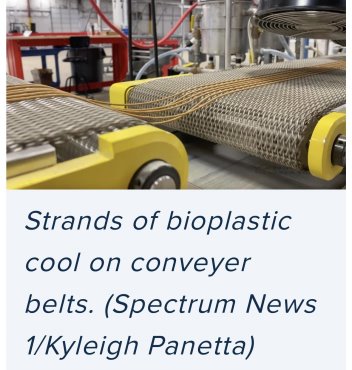

Wondering how plants are turned into a material that mimics the look, feel and durability of traditional petroleum-based plastic? Watch HERE(segment run time is 3 min. 49 seconds) as PlantSwitch CEO, Dillon Baxter demonstrates the process.

How long does it take for a PlantSwitch bioplastic fork to naturally break down and decompose? Just a few months.

How long does it take a traditional petroleum-based plastic fork to naturally break down and decompose? 1,000 years!

PlantSwitch will soon be announcing some other big deals in early 2024 with three publicly traded companies in the food, cosmetics and pharmacy sectors.

Why PlantSwitch bioplastic is being touted as the best plant-based plastic replacement solution to ever hit the market?

PlantSwitch offers the first affordable, drop-in plastic alternative solution that does not require companies to replace their current plastic processing equipment.

PlantSwitch offers a tactile and performance match to traditional plastic. It feels like plastic, looks like plastic, and performs like plastic. It has the same bend, flex and strength.

Previous bioplastics were only able to be composted in an industrial facility. PlantSwitch bioplastic products easily and quickly break down in common backyard composting bins and countertop composters. Watch HERE.